Marine Boilers

Increase operating efficiency and reduce emissions by preventing slagging and fouling on marine boilers through online cleaning

Marine Boilers

Blending of different types of fuels, including VLSFO, can result in increased rates of fouling due to the different characteristics of the fuel. As a result of this, the efficiency of the boiler decreases, fuel consumption rises and emissions increase.

Using Therma-Chem MB9 will prevent this.

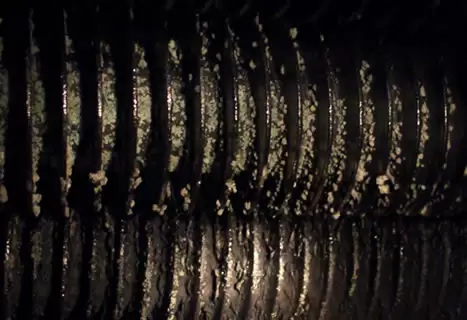

Before Therma-Chem

Before treatment, sticky, sulphurous and corrosive deposits are clearly visible.

After Therma-Chem

After treatment, all sulphurous deposits have been removed. Dry dust is all that remains.

How MB9 Works

MB9 is a mildly alkaline solution that is designed specifically to clean marine boilers online. Similar to land based operations, MB9 is injected using Therma-Chem’s proprietary injection equipment which will be installed on the ship. Injected directly into the combustion chamber, MB9 is carried by the flue gas throughout the unit encountering all heat transfer surfaces including the wall tubes, superheaters, reheaters and economisers.

MB9 reacts with exisiting hard deposits on tubes by increasing their melting point and reduces them to soft powdery ash.

This allows units to maintain high thermal efficiencies or recover capacity (if this was limited by fouling). MB9 also neutralises sulphur deposits on the cold end of the flue gas path preventing cold end corrosion and eases man entry during a maintenance or inspection shutdown.

In addition, MB9 will reduce NOx, SOx and Carbon emissions through reductions in fuel consumption.

Using MB9 ultimately results in improved heat transfer, prevention of both high temperature and low temperature corrosion, improved operating efficiency and reduced emissions.

Installation

Therma-Chem have significant experience in installing our injection equipment on ships, particularly LNG vessels. During docking, Therma-Chem engineers will install our equipment on the ship to enable simple injections of MB9 into the boiler. Injection lances are inserted alongside the burners allowing the chemical to expand and be carried throughout the boiler with the flue gases.

Application Methods

Maintenance Dosing

Applied daily, MB9 keeps boilers clean and prevents costly drop offs in performance and avoids unnecessary increases in fuel consumption. This removes the need to stop the vessel for cleaning. Typically, only one injection of chemical is required each day.

Online Recovery

When a boiler is load and/or temperature restricted mid-run and there is no window to shut down for maintenance, MB9 is introduced to recover performance. Injected 3-4 times per day over a period of 30-90 days, depending on the severity of the fouling, MB9 can target any part of the boiler loosening deposits and restoring performance.

Pre Shutdown Cleaning

Utilised in the run up to a shutdown to facilitate a more effective and easier clean of a boiler, MB9 can be applied 3-4 times per day for a period between 30 – 90 days.This ensures that during the shutdown, cleaning is more effective, easier, quicker and any vanadium pentoxide and sulphuric deposits are neutralised, dry, and entry into all areas of the boiler is safe and comfortable.