CO Boilers & Waste Heat Boilers

Increase efficiency and prevent unplanned shutdowns via online cleaning.

Online Boiler Cleaning Specialists

CO Boilers and Waste Heat Boilers often experience deposition issues as a result of contaminants in the flue gasses coming from upstream units.

Therma-Chem are specialists in dealing with fouling which arises from the flue gases, whether it is catalyst fines being deposited or incombustibles from refinery or waste gases.

By applying our products online, Therma-Chem can maintain high operational efficiencies and prevent any loss in performance of the downstream boilers minimising the impact that they may have on the upstream units.

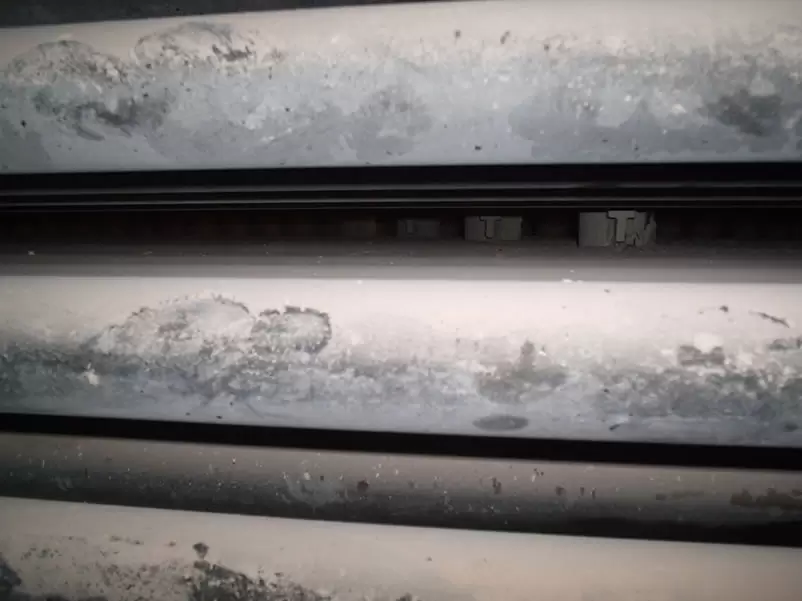

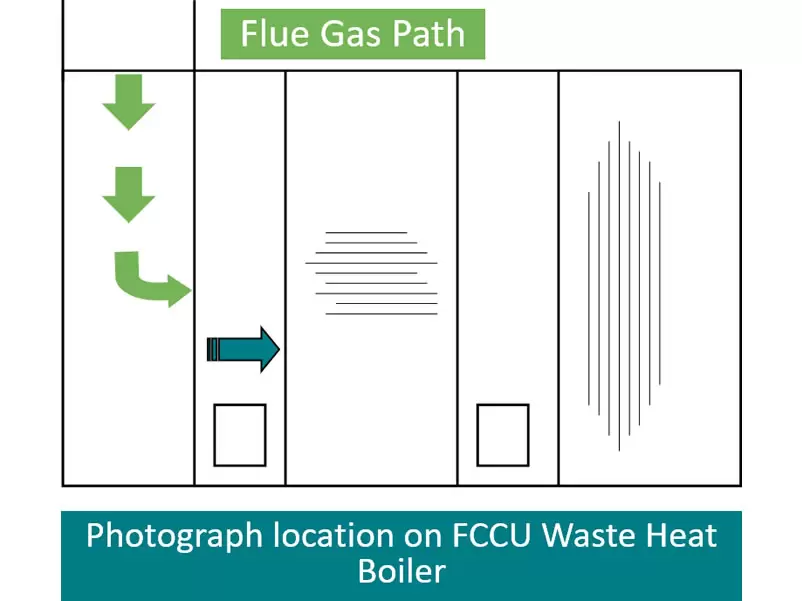

All heavy and sulphuric deposits completely removed from the steam tubes on a FCCU Waste Heat Boiler after online cleaning by Therma-Chem. Only light dust remains that can be brushed away by hand.

How Does FS12 Work

Therma-Chem’s FS12 is an mildly alkaline solution containing nitrates that is designed specifically to clean boilers online. Using Therma-Chem’s proprietary injection system, the liquid is injected directly into the furnace, vaporises and is carried by the flue gas through the unit, encountering all heat transfer surfaces including the superheaters, economiser, and air pre-heater.

FS12 reacts with existing hard deposits and fouling on tubes by increasing their melting point and reduces them to soft powdery ash.

FS12 also neutralises sulphur deposits on the cold end of the flue gas path preventing cold end corrosion and eases man entry during a maintenance or inspection shutdown.

Therma-Chem have many years of experience in cleaning both CO Boilers and Waste Heat Boilers online and specialise in dealing with catalyst based fouling downstream of FCCs resulting in increased efficiency and availability.

Application Methods

FS12 is traditionally applied to process heaters in one of three ways:

Maintenance Dosing

Applied daily, FS12 keeps units clean and prevents costly drop offs in performance and avoids the possible need for shutdowns during the operating campaign. This is the most common method of application with some customers having used Therma-Chem every day for 15 years across multiple units.

Online Recovery Cleaning

When a unit is load and/or temperature restricted mid-run and there is no window to shut down for maintenance, FS12 is introduced to recover performance. Injected 3-4 times per day over a period of 30-90 days, depending on the severity of the fouling, FS12 can target any part of the unit loosening deposits and restoring performance. We would then recommend switching to Maintenance Dosing to prevent a drop-off in performance recurring.

Pre Shutdown Cleaning

Utilised in the run up to a shutdown to facilitate a more effective and easier clean of a unit, FS12 can be applied 3-4 times per day for a period between 30 – 90 days.This ensures that during the shutdown, cleaning is more effective, easier, quicker and any sulphuric deposits are neutralised, dry, and entry into all areas of the unit is safe and comfortable.