World leading experts in the online cleaning of boilers, fired-heaters and rotating equipment.

World leading experts in the online cleaning of boilers, fired-heaters and rotating equipment

About Therma-Chem

Since 1984, Therma-Chem have worked with some of the world’s biggest power plant owners and refineries including Shell, ExxonMobil, PetroChina and BP to develop market leading products that increase efficiency, reduce emissions and restore capacity.

We work closely with our customers to demonstrate that our products provide both economical and ecological savings and help the world become a greener place. We are always exploring new technologies to solve new challenges and work closely with universities and governmental organisations to enhance our offering for our clients.

Applications

Power Plants

Increase boiler efficiency and reduce emissions by preventing fouling and ash deposits.

Refineries

Maximise ouput, reduce downtime and eliminate corrosion via our online cleaning solutions.

Shipping

Prevent slagging and fouling on marine boilers, maximising fuel efficiency and reducing emissions.

Products

Using FS12 will ultimately result in increased efficiency, reduced emissions and the prevention of corrosion.

Designed to remove slagging and fouling online, FS12 is an online boiler cleaning chemical that eliminates deposition on all heat exchange surfaces from the furnace through to the stack.

View More

Created specifcially to target rotating equipment including Gas Turbines and Expanders within FCC units.

Therma-Chem’s Turbo-Mor is applied online to prevent corrosion of blades and other components by neutralising corrosive substances such as sulphur and vanadium.

View More

MB9 will remove slagging and fouling throughout the boiler and will reduce the time spent in dock for cleaning.

Produced for the shipping industry, MB9 was specifically designed to target marine boilers and the unique difficulties they present.

View More

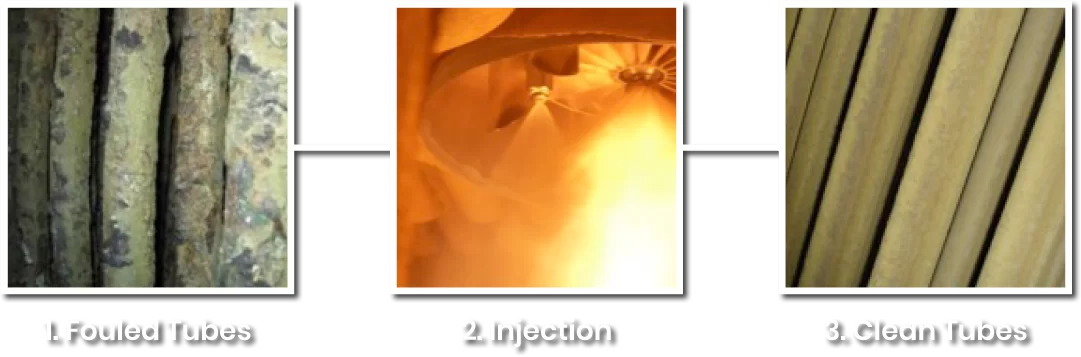

How Our Products Work

All our products are mildly alkaline solutions that are designed specifically to clean online. Using Therma-Chem’s proprietary injection system, the liquid is injected directly into a unit, vaporises, and is carried by the flue gases throughout the unit encountering all heat exchange surfaces. The chemical forms a thin micron coating which penetrates, loosens and disintegrates deposits, protecting surfaces from corrosion and prevents the accumulation of new deposits.

Case Studies

Contact Therma-Chem Today!

Become a Global Representative

Clients We Have Worked With