FS12

Eliminate ash deposition in boilers and fired-heaters via online cleaning.

FS12

Our UN approved methodology for reducing emissions, FS12 is designed to remove slagging and fouling online within boilers and process heaters.

FS12 targets all heat exchange surfaces from the combustion chamber through to the stack. Using FS12 will result in increased efficiency, restored capacity and the prevention of corrosion.

How FS12 Works

Therma-Chem FS12 is an alkaline solution designed to clean online. It is not a fuel additive but rather a post-combustion treatment of ash deposits.

It is injected directly into the combustion or radiant section, whilst on-load, using our proprietary injection equipment.

The chemical gasifies and expands, creating a fine mist which is carried throughout the unit by the flue gasses. The mist condenses on all heat exchange surfaces and loosens deposits, converting them to soft, powdery ash. This allows units to increase efficiency and recover any lost capacity if limited by ash deposition. Moreover, FS12 will also neutralise any sulphur deposition in the back end of the boiler eliminating cold-end corrosion and allowing for safer, quicker turnarounds.

FS12 is a safe, environmentally friendly product uniquely designed to target slagging and fouling.

Application of FS12

Therma-Chem work closely with technical, operational, and maintenance teams to ensure that FS12 application is optimised for each unit. We provide free data analysis services and work closely with clients to monitor the application and ensure that we achieve our mutual aims.

FS12 can be applied in the following ways:

Maintenance Dosing

Applied daily, FS12 keeps units clean and prevents costly drop offs in performance and avoids the possible need for shutdowns during the operating campaign. This is the most common method of application with some customers having used Therma-Chem every day for 15 years across multiple units.

Online Recovery

Primarily the main way of introducing Therma-Chem to clients, FS12 is applied when a unit is load and/or temperature restricted mid-run and there is no window to shut down for maintenance. Injected 3-4 times per day over a period of 30-90 days, depending on the severity of the fouling and the configuration of the unit, FS12 can target any part of the unit loosening deposits and restoring performance.

Pre-Shutdown Cleaning

Utilised in the run up to a shutdown to facilitate a more effective and easier clean of a unit, FS12 can be applied 3-4 times per day for a period between 30 – 90 days.This ensures that during the shutdown, cleaning is more effective, easier, quicker and any vanadium pentoxide and sulphuric deposits are neutralised, dry, and entry into all areas of the unit is safe and comfortable.

Benefits of FS12

FS12 works throughout boilers and heaters offering the following key operationsal benefits:

- Boilers are cleaned online requiring no downtime

- Heat transfer improves by reduction of slagging and fouling, thus increasing overall efficiency

- Prevents and restores loss of capacity related to fouling

- No line of sight required to eliminate deposits

- Eliminates both high and low temperature corrosion, in particlular vanadium and sulfur corrosion

- Reduces overall emissions through efficiency improvements and online cleaning of ESPs

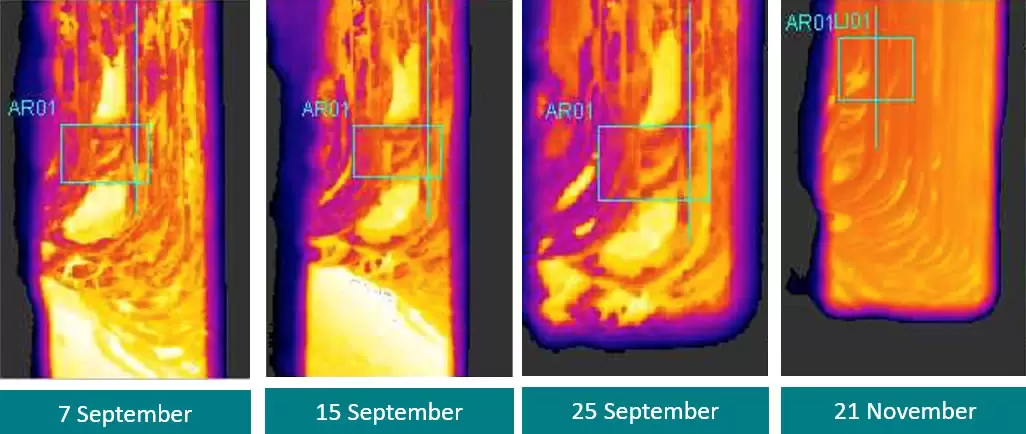

The images above show the transition of the heat balance being restored on a 525 t/hr boiler from 7 September through to 21 November. This is a fantastic example of how Therma-Chem recovers boiler performance via online cleaning.