Biomass Power Plant

Increase availability of biomass plants by eliminating unplanned shutdowns through the reduction of ash deposition.

Online Boiler Cleaning Specialists

Therma-Chem are specialists in the online cleaning of boilers and have worked succesfully with several biomass fuels including wood chips, wood pellets and waste.

With regards to deposition, biomass fuels are similar to fossil fuels as the composition of the ash deposits that form after combustion have similar properties and components. Of course, the type of biomass and quality of the biomass being burned impacts upon the deposition process significantly. For example, the levels of sulphur, sodium, potassium, lead and chlorine in the fuel will determine the rate and volume of the deposits.

As world-leading experts in eliminating ash deposition, Therma-Chem can asses the deposits and recommend a course of action to increase the efficiency of the boiler and increase availability.

The above images show the transformation of a biomass deposit after treatment by Therma-Chem. The deposit has become more brittle and easier to remove.

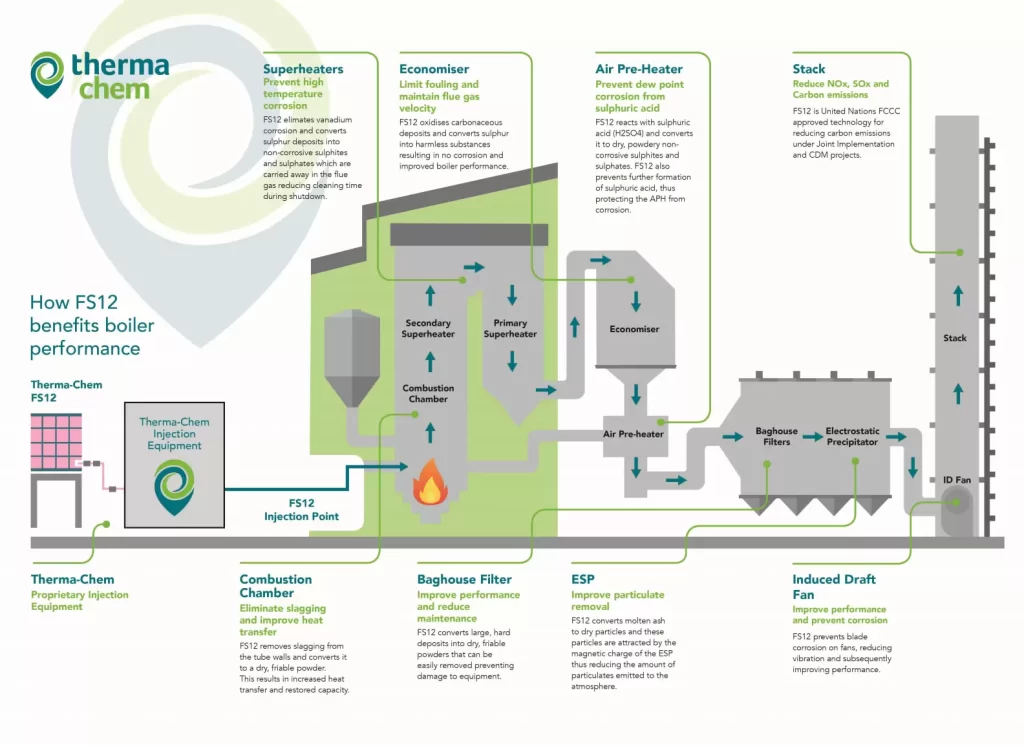

How FS12 Benefits Boiler Performance

How Does FS12 Work

Therma-Chem’s FS12 is an mildly alkaline solution containing nitrates that is designed specifically to clean boilers online. Using Therma-Chem’s proprietary injection system, the liquid is injected directly into the combustion chamber, vaporises and is carried by the flue gas through the unit, encountering all heat transfer surfaces including the water wall, superheaters, economiser, and air pre-heater.

FS12 reacts with existing hard deposits and fouling on tubes by increasing their melting point and reduces them to soft powdery ash.

This allows units to maintain high thermal efficiencies or recover capacity (if this was limited by fouling). FS12 also neutralises sulphur deposits on the cold end of the flue gas path preventing cold end corrosion and eases man entry during a maintenance or inspection shutdown.

In addition, FS12 will reduce NOx, SOx and Carbon emissions via efficiency improvements.

Using FS12 ultimately results in improved heat transfer, prevention of both high temperature and low temperature corrosion, improved operating efficiency and reduced emissions.

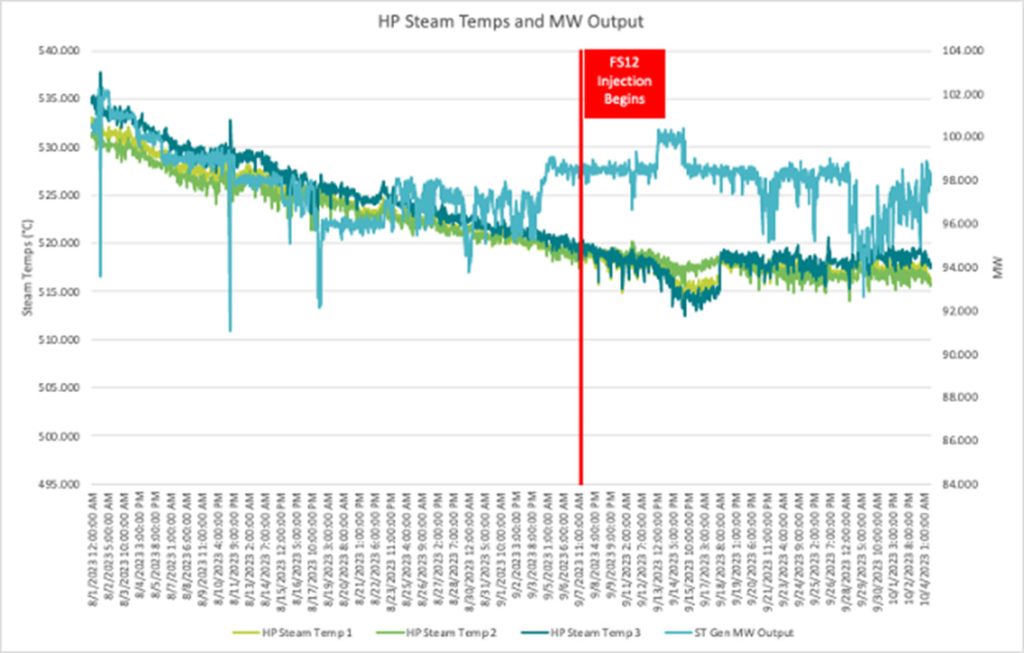

The graph above shows the impact of the introduction of FS12 in arresting the decline in the superheated steam temperatures. This is an excellent example of the online cleaning effects of FS12 on biomass boilers.

Application Methods

FS12 is traditionally applied to process heaters in one of three ways:

Maintenance Dosing

Applied daily, FS12 keeps units clean and prevents costly drop offs in performance and avoids the possible need for shutdowns during the operating campaign. This is the most common method of application with some customers having used Therma-Chem every day for 15 years across multiple units.

Online Recovery Cleaning

When a unit is load and/or temperature restricted mid-run and there is no window to shut down for maintenance, FS12 is introduced to recover performance. Injected 3-4 times per day over a period of 30-90 days, depending on the severity of the fouling, FS12 can target any part of the unit loosening deposits and restoring performance. We would then recommend switching to Maintenance Dosing to prevent a drop-off in performance recurring.

Pre Shutdown Cleaning

Utilised in the run up to a shutdown to facilitate a more effective and easier clean of a unit, FS12 can be applied 3-4 times per day for a period between 30 – 90 days.This ensures that during the shutdown, cleaning is more effective, easier, quicker and any sulphuric deposits are neutralised, dry, and entry into all areas of the unit is safe and comfortable.