Biomass Boiler Efficiencies

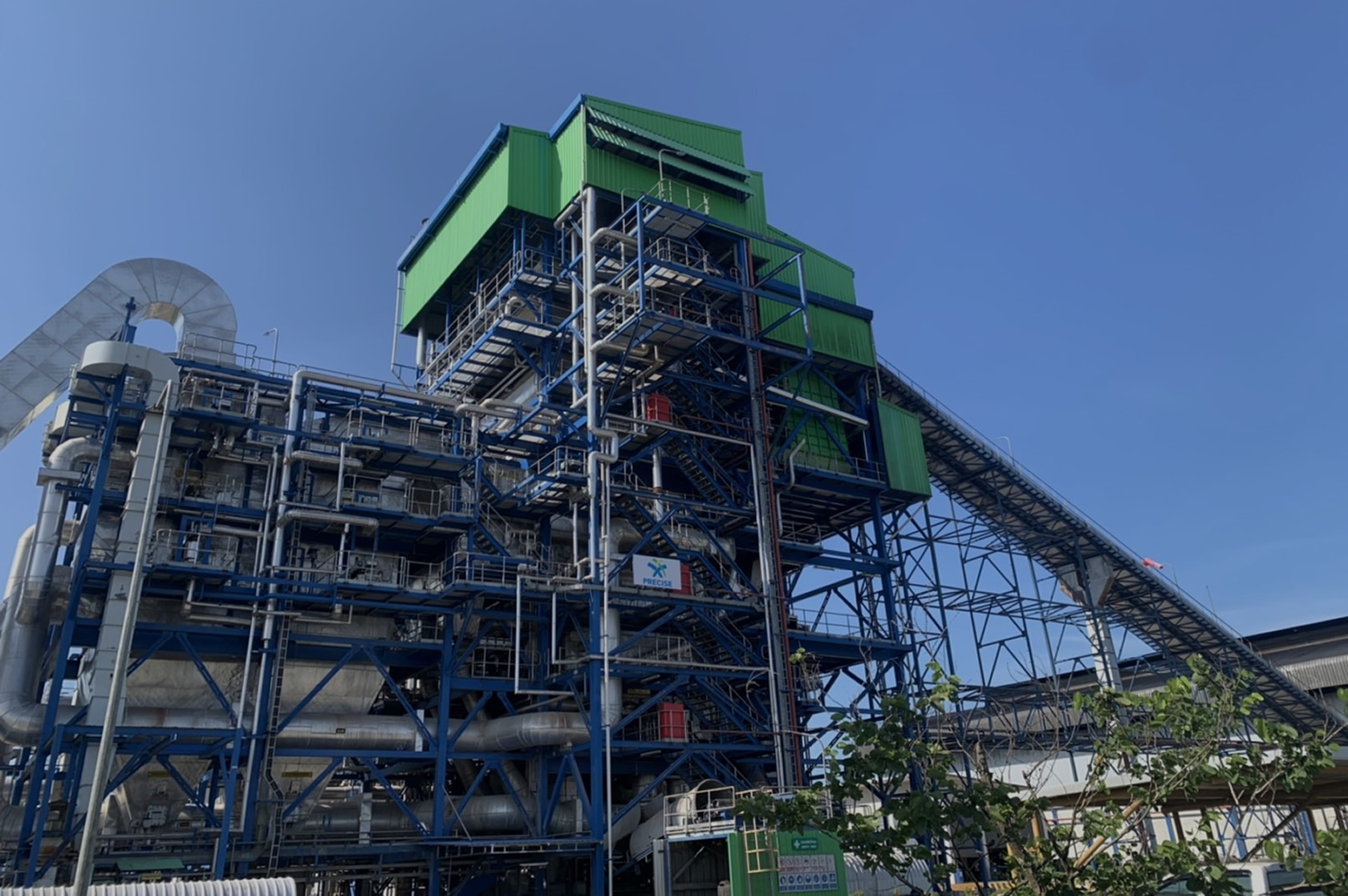

Therma-Chem increased the boiler run length and reduced time spent on manual cleaning at Songkhla Biomass Power Plant in Thailand.

Objectives

The 10MW biomass boiler was firing 80% Wood Chips and 20% EFB, a product of Palm Oil extraction. As a result, the ash deposition in the boiler increased due to the high potassium, sodium, and chlorine content.

Due to the lower ash fusion temperature, the furnace walls experienced significant hard and molten slag deposits.

Consequently, the boiler needs to shut down every 3-6 months for manual cleaning. The cleaning takes at least 3-4 days to remove slag from the furnace water wall.

Solution

Therma-Chem undertook a 97-day injection programme to monitor the operating data and compare the condition of the boiler at a planned shutdown. The aim was to increase the boiler run length, increase the boiler efficiency, and change the nature of the ash deposits saving time for manual cleaning.

Outcomes

Increased boiler efficiency by 0.5% by reducing dry flue gas loss.

Maintain stable furnace gas exit temperature and boiler exit temperature in line with designed condition.

Reduction in slagging in the furnace.

All deposits were much softer than usual and easier to remove.

Opportunity to increase availability and burn lower quality fuels.

At a Glance

Challenges

• Hard and molten slag in the furnace

• Shutdowns every 3 – 6 months for manual cleaning

• Manual cleaning taking up to 4 days.

Gains

• Increased availability

• Improved boiler efficiency

• Cost savings

“The effect of FS12 on reducing slagging and fouling on heating surface contributed to the maintaining adequate heat transfer and flue gas temperature profile in and out each heating surface.”

Mr. Arif Turwemu, Performance Engineer, SKB Power Plant, Thailand