Vacuum Tar Residue & Fuel Gas Fired Boiler

160 MW boiler (630 T/Hr) firing a mixture of Vacuum Tar Residue and Fuel Gas

Problem

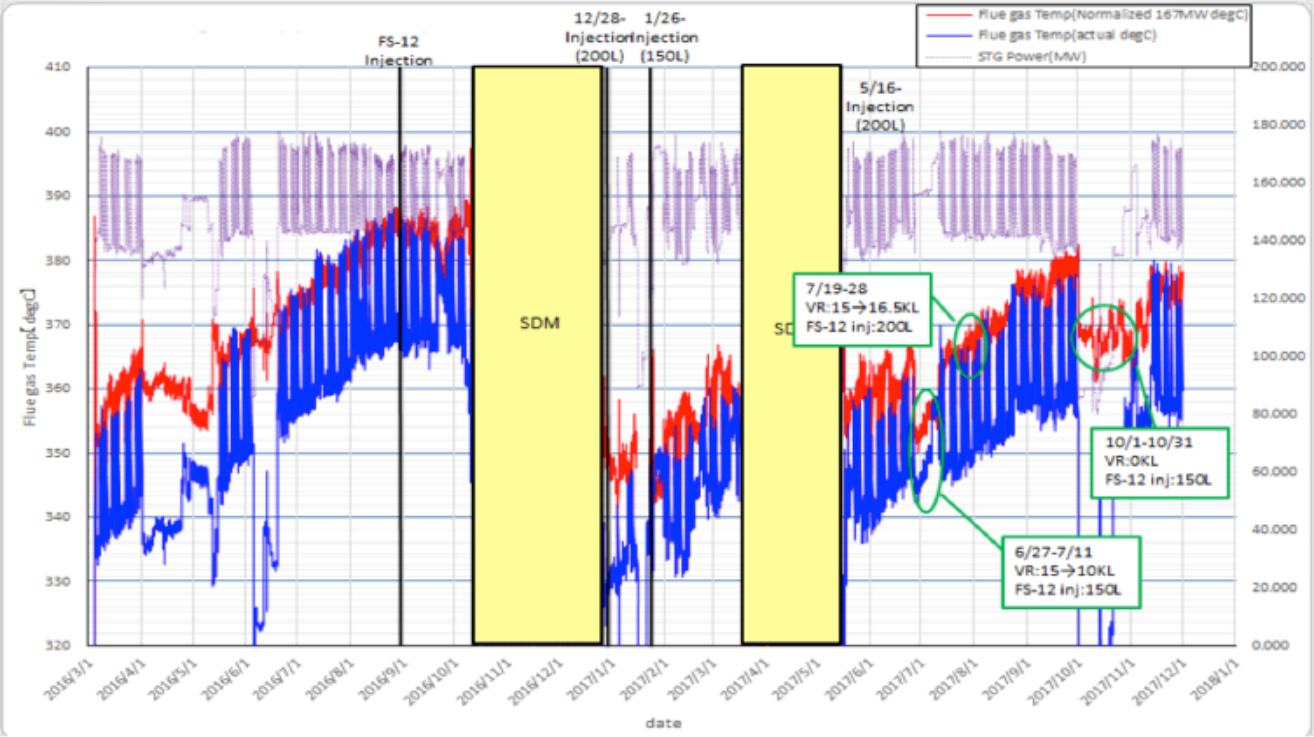

The boiler experienced heavy fouling on their superheaters and economiser causing flue gas temperatures to increase. This resulted in the boiler having to be shut down earlier than anticipated. In addition, they experienced corrosion on the air preheater extending maintenance time and jeopardising the metallurgy.

After Therma-Chem Treatment

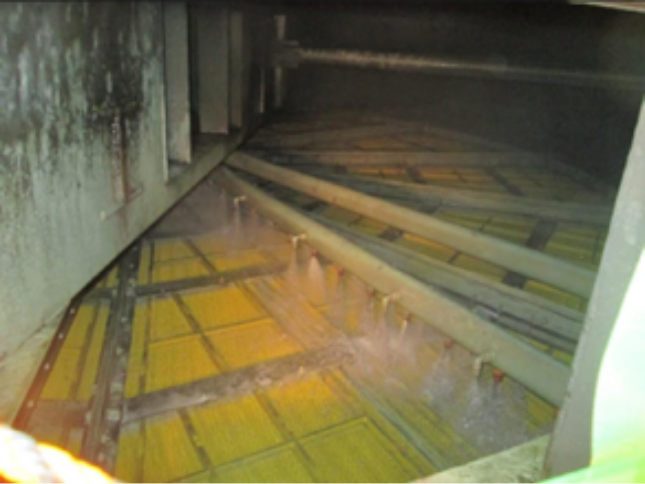

Fouling was removed from both the superheaters and the economiser significantly reducing the flue gas exit temperature. This enabled the refinery to run the boiler for longer than they were previously able to. Corrosive sulphur deposits were neutralised in the air pre-heater enabling a more efficient and quicker clean at shutdown. The pictures to the right clearly show significant sulphur deposits on the APH baskets and carbonaceous deposits on the walls. After Therma-Chem treatment, these sulphur deposits have been converted to non-corrosive sulphites and sulphates and the carbonaceous deposits have been oxidised from the wall.

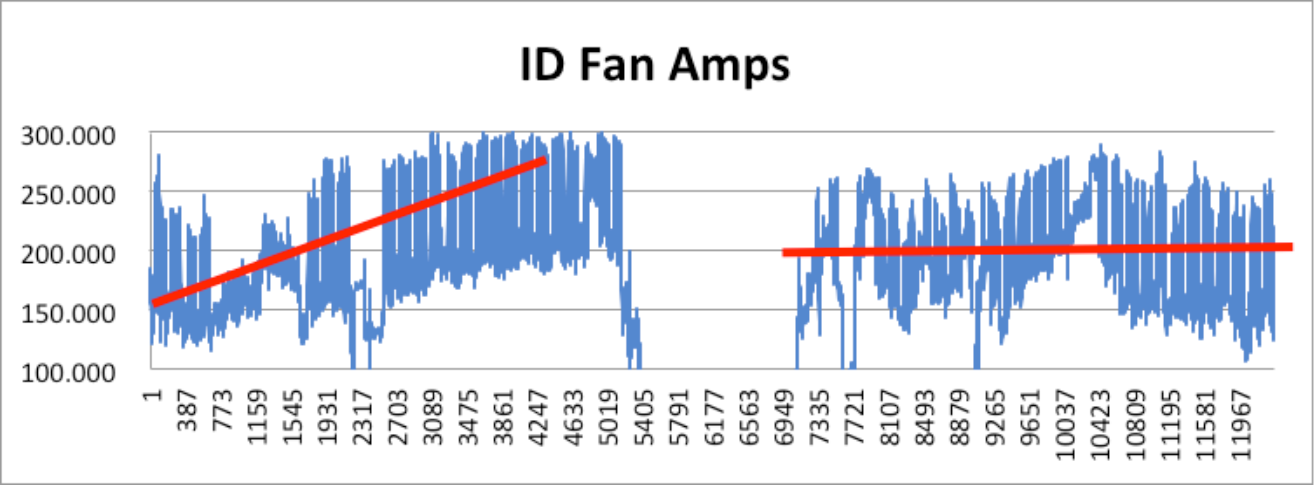

Therma-Chem have also had a significant impact upon the operation of the ID Fan. Prior to FS12 injections, the trend is of increasing ID fan amps. However, after treatment it is clear that the ID fan amps are relatively stable. ESP performance also improved requiring less maintenance and downtime for cleaning resulting in significant savings by returning the boiler to full load earlier than anticipated. The pictures to the right illustrate the difference in the cleanliness, and thus effectiveness, of the electrodes before and after Therma-Chem treatment. As a result of the improved boiler condition, the plant no longer need to use a magnesium oxide fuel additive and intend to increase the ratio of fuel oil to fuel gas burning, realising significant savings by burning cheaper fuel.