Preventing Unplanned Shutdowns saves power plants £millions

Unplanned shutdowns in power plants have huge implications on efficiencies and costs. This is a massive problem world-wide, particularly in biomass plants where different fuels with varying moisture and ash content are being used. Cost, availability, and blending of fuels can result in significant slagging and fouling deposits resulting in unplanned shutdowns.

Plants want to avoid unplanned shutdowns to maximise profits and therefore need solutions to keep their boilers clean. Any unplanned shutdown can cost power plants millions in lost revenue.

When the performance of a boiler starts to decline, suggesting that the plant may be going towards an unplanned shutdown, a tried and tested solution is for Therma-Chem to inject the FS12 chemical into the furnace to stabilise the performance or, if time allows, recover the performance online. Results of the chemical injection process can be seen anywhere between 7 days and 30 days, using a less harsh treatment than other chemical competitors.

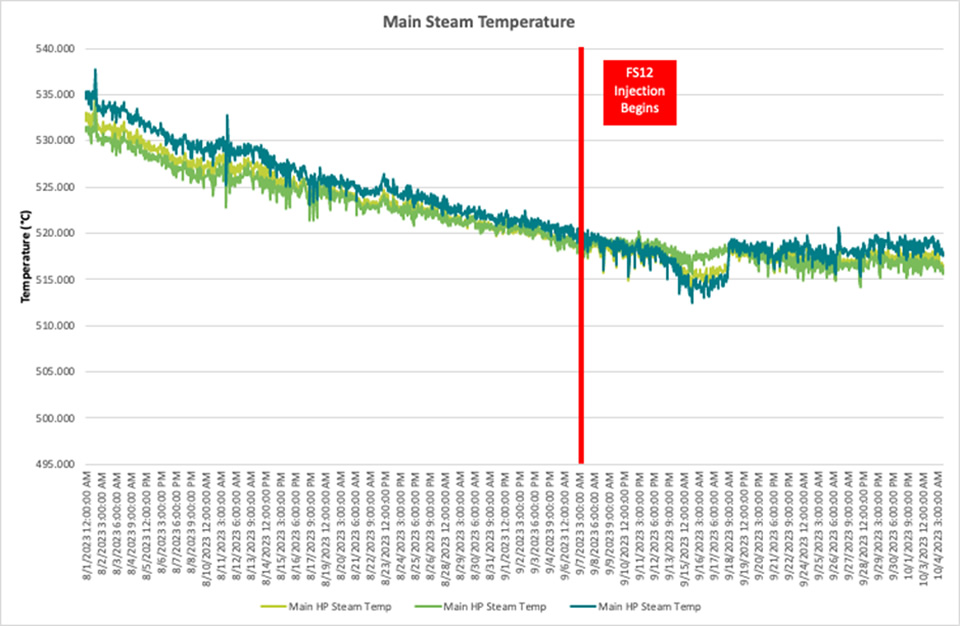

The image below shows how the introduction of FS12 arrested the decline of the superheated steam temperatures and stabilised the boiler performance of one of our biomass clients within 10 days. This can prevent unnecessary shutdowns.

Table 1: Superheated Steam Temperatures on a Biomass Power Plant Boiler before and after the introduction of FS12

Biomass Power Plant Case Study

A great example is the work we have done for Songkhla Biomass Power Plant in Thailand who are burning wood pellets and EFB to produce electricity. The plant was experiencing regular unplanned shutdowns due to slagging and fouling. After introducing Therma-Chem’s chemical, their availability has significantly increased, and the boiler efficiency has improved.

The following table shows the efficiency improvements achieved after only 79 days. This efficiency improvement was achieved on a boiler that shut down every 3-4 months.

Table 2: Boiler Efficiency Before and After Therma-Chem Treatment

| Date | Boiler Net Energy Output | Load | Boiler Efficiency | Fuel |

|---|---|---|---|---|

| 1 November 2022 | 115,912,000 kJ/h | 9.1 MW | 72.79% | 15,561 kg/h |

| 19 January 2023 | 115,912,000 kj/h | 9.1 MW | 73.40% | 15,432 kg/h |

To find out more about how Therma-Chem helped this client, read the case study here.

“Unplanned Shutdowns are a huge headache for the power industry. We know our chemical can quickly stabilise the performance of the boiler and recover performance, online. This is essential for any power plant to maintain efficiencies across the plant and avoid the huge costs incurred when a boiler is shutdown.”

Therma-Chem’s Technical Sales Manager Gerry O’Rourke